The development of simple and rapid diagnostic screening tests continues to be critically important in helping control the COVID-19 pandemic. Having the ability to expand rapid testing, isolate infected individuals quickly, and implement contact tracing will help limit the spread of the disease.

Currently, the most widely used method for detecting SARS-CoV-2 (the virus that causes COVID-19) is the nasal swab RT-qPCR test. In this test, a sample is collected by inserting a nasopharyngeal swab into a person's nose. The swab is then placed into a tube of viral transport media and the tube is sent to a testing lab. RNA is extracted from the sample and subsequent RT-qPCR is performed. Test results are typically received in 2-4 days.

In response to the long test result turnaround times, researchers at the University of Illinois at Urbana-Champaign have developed a saliva-based COVID-19 test, I-COVID. This test is easier to administer than swab-based tests, is cost-effective, and results can be obtained in 6-12 hours. Here, we discuss SHIELD T3, an organization founded by the University of Illinois to help expand the use of the I-COVID test. We describe their testing method and how Gilson liquid handling products are used to facilitate the workflow.

One of the features of the system is that the test has a very high degree of sensitivity, and so we're often able to detect individuals that are infected before they become highly infectious, allowing them to be isolated before further spread happens

- Christian Messmacher, Chief Operating Officer at SHIELD T3

What is SHIELD T3?

SHIELD T3 is a university-run organization created by the University of Illinois to expand the reach of testing using the I-COVID test both nationally and overseas. The company was formed in July of this year, and they are currently setting up laboratories with the intention of replicating the success of the COVID testing program at the University of Illinois Urbana-Champaign campus.

The name SHIELD T3 is a reference to the approach they employ ‒ target, test, tell. They target which populations to test and at what frequency, test those populations, and quickly report the test results digitally and employ contact tracing. This strategy allows for isolation of those who test positive, helping to limit the spread of the disease.

"Testing has to act in concert with a very active targeting of the people who need to be tested along with a very active isolation and quarantine program," says Christian Messmacher, Chief Operating Officer of SHIELD T3. "One of the features of the system is that the test has a very high degree of sensitivity, and so we're often able to detect individuals that are infected before they become highly infectious, allowing them to be isolated before further spread happens."

Fast, Sensitive Saliva-based COVID-19 Test

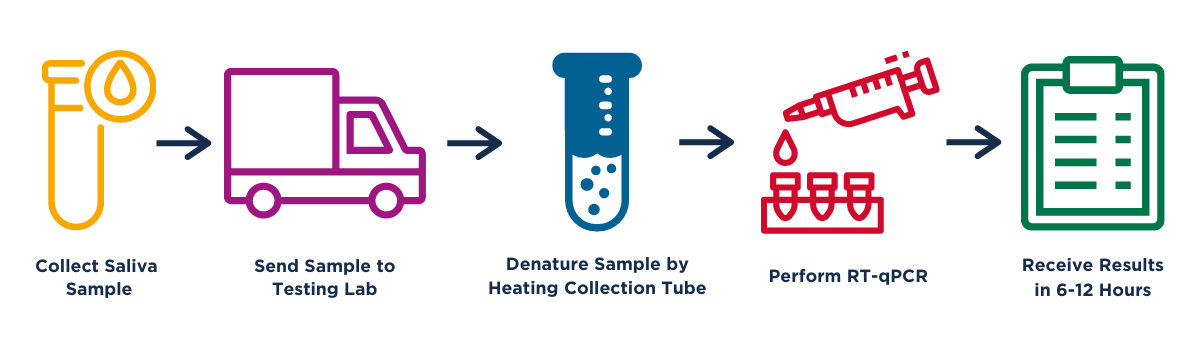

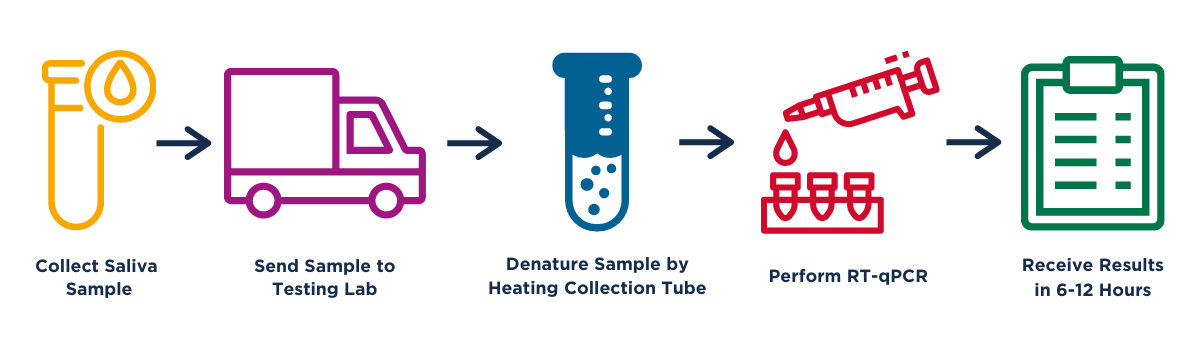

To perform the I-COVID test, an individual simply deposits saliva into a tube, closes the tube, and the tube is sent to a testing lab. In the lab, the sample is denatured by heating the closed tube, and then RT-qPCR analysis is performed on a real-time PCR instrument (Figure 1). Negative results get reported immediately and positive results get retested for confirmation and accuracy.

This method has several advantages over the standard swab-based COVID-19 test. "The most important advantage is that it bypasses the RNA extraction step, which is a significant time and supply chain problem in the current testing regime. It is also a very simple and low-discomfort way to obtain a sample compared to nasopharyngeal swabs. And it produces very fast results," explains Messmacher.

Figure 1. Schematic of the saliva-based I-COVID test procedure

Simple, Powerful Tools to Increase Workflow Efficiency

According to Messmacher, for a high-throughput lab to operate efficiently, there needs to be a consistent process that gets done exactly the same way every time to ensure stable and predictable testing outcomes. Automating some processes, such as preparing samples in 96- and 384-well plates, helps eliminate errors, facilitates the job, and allows efficient scale-up of the testing process. Space considerations are also important. "We wanted something that would give us repeatability, but that would also minimize the footprint," says Messmacher.

SHIELD T3 has incorporated several Gilson liquid handling tools into their testing workflow, including PLATEMASTER®, PIPETMAX®, and TRACKMAN® Connected.

PIPETMAX and PLATEMASTER for Accurate and Fast Sample Transfers

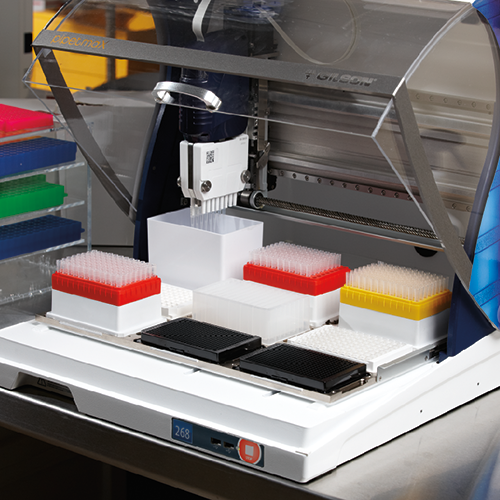

PIPETMAX is an automated pipetting solution for the efficient processing of high-throughput biological assays (Figure 2). It helps improve accuracy, reproducibility, and consistency among samples. Its benchtop size allows it to easily fit into any lab. SHIELD T3 uses PIPETMAX in their sample preparation to transfer saliva samples from the original collection vials to 96-well plates, essentially eliminating the manual work of that step.

Figure 2. The compact PIPETMAX automates sample preparation for increased speed, accuracy, and reproducibility

They also use PLATEMASTER for preloading 96- and 384-well plates with reagents and for sample transfers from 96-well plates to 384-well plates for RT-qPCR, reducing the amount of work for lab personnel. PLATEMASTER is an easy-to-use, accurate tool for high-throughput manual pipetting of microplates (Figure 3). It accelerates repetitive manual pipetting, reduces errors, and eliminates well-to-well and plate-to-plate variance, greatly improving reproducibility.

Figure 3. PLATEMASTER for high-throughput manual pipetting of 96-and 384-well plates

Connected Pipettes Reduce Errors

SHIELD T3 has also incorporated TRACKMAN Connected into their workflow to help reduce pipetting errors. TRACKMAN Connected is a tablet that makes pipetting on 96- and 384-well plates faster and more reliable. Designed to communicate with PIPETMAN® M Connected via Bluetooth®, the tablet interacts in real-time with the pipette and guides the user through the protocol with the installed PipettePilot® app. The app displays where, when, and how much to pipette with real-time interactions to prevent errors.

"When we looked at the testing workflow, it became very apparent that any manual operation would come with a high risk of making errors when transferring samples from one plate to another. We were looking for a simple way to reduce the probability of those errors happening. When we saw TRACKMAN, we thought here is a very simple solution that works," says Messmacher.

In addition, they are finding features of PIPETMAN M Connected, such as the range of pipetting modes, to be valuable. "We are finding them to be very flexible, very powerful tools," says Messmacher.

Figure 4. TRACKMAN Connected, designed to communicate with PIPETMAN M Connected is a tablet with exclusive accessories and applications that make pipetting on 96-and 384-well plates faster and more reliable

Different Pipettes for Different Tasks

They have also used other Gilson pipettes in their work and have found that having a variety of pipettes gives them flexibility. "It's a matter of having the right tool for the job," says Messmacher.

In particular, they have had success with MICROMAN® E, a positive-displacement pipette, for working with the saliva samples. "We have found that saliva is a fluid with incredibly variable viscosity. Especially in the symptomatic population, there is incredibly high viscosity of the saliva samples, and the positive-displacement pipettes seem to work a lot better for handling that kind of variability," explains Messmacher.

Improved Workflow Efficiency for Expanded Testing

Efficient methods and tools to expand testing and improve turnaround times for COVID-19 tests are urgently needed to control the spread of the virus. The SHIELD T3 I-COVID test is a rapid, easy-to-administer, saliva-based test that requires no RNA extraction step and produces results quickly. Gilson liquid handling tools help improve the efficiency of the testing workflow by accelerating the process and reducing errors.

Liquid Handling Tools to Accelerate Your Testing Workflow

Contact us to learn more about how our solutions can help you increase productivity and expand your testing capabilities.

CONTACT US