Human endeavor and progress are intrinsically linked to our technology. We are now living in an age where robotics and automation touch almost every facet of our lives. In laboratories, robotic liquid handling systems revolutionize everything from DNA sequencing to automated drug discovery and high-throughput screening.

The sheer variety of robotic liquid handling systems available for labs has increased dramatically over the last decade. Market analysis predicts that the automated liquid handling solutions market will grow by more than 7% over the next few years, reaching $4.65 billion by 2025.

These systems are becoming more popular because of the advantages they offer compared to manual liquid handling workflows. Increased accuracy, speed, and throughput are possible using automated liquid handling systems. When it comes to choosing the right liquid handling robot for your screening, sequencing, bioassays, sample preparation, or liquid weighing, you'll need to evaluate each automated solution according to your precise needs.

What Are Robotic Liquid Handling Systems?

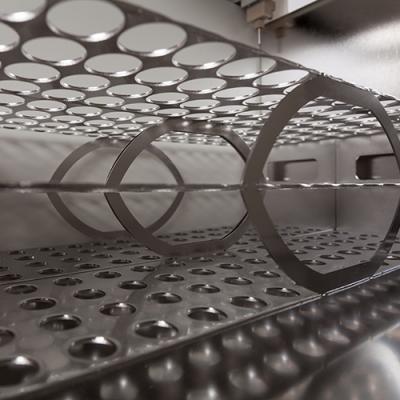

Automated or robotic liquid handling systems are a class of devices that perform various liquid handling tasks in laboratories, including pipetting, sample preparation, and microplate washing. With these devices, laboratories can save on labor and free up resources to focus on analysis work instead of performing repetitive liquid handling tasks.

Liquid handling robots come with a host of features and integrations that allow laboratories to automate many of the liquid handling steps used in the workflow. As labs can set up walkaway or unattended protocols with these solutions, a liquid handling robot can ensure precision and repeatability compared to manual sample processing. Automated liquid handling systems come in many different shapes and sizes, with many capabilities, configurations, and accessories available for each platform.

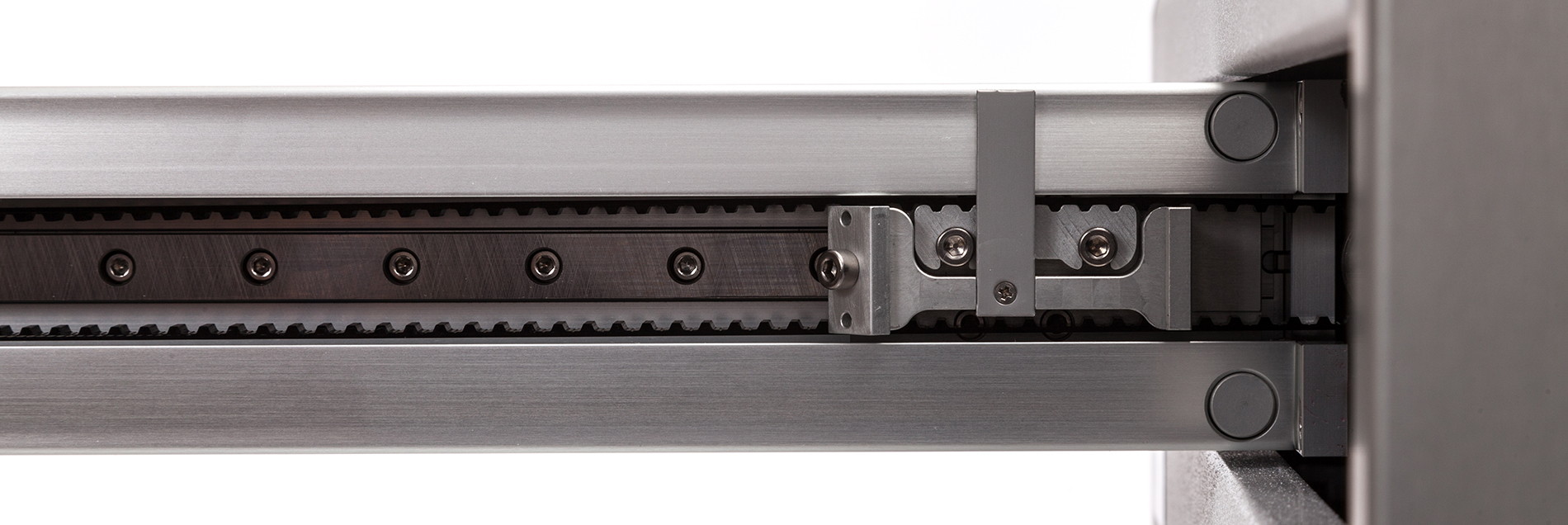

The typical architecture involved in a robotic liquid handling system includes:

- A control system that manages the movement of the robotic arms

- Washing station to clean the dispensing heads of the system

- Sensors that feedback information to the control system and maintain accuracy

- Dispensing heads that control the flow of liquids into the vessels (usually on an x and y plane)

Platforms are programmable, allowing you to set up a range of protocols depending on your required application.

Robotic liquid handling systems are a class of devices that perform various liquid handling tasks in laboratories, including pipetting, sample preparation, and microplate washing. With these devices, laboratories can save on labor and free up resources to focus on analysis work...

What Applications Use Automated Liquid Handling Robots?

Wherever there is a need to increase throughput while maintaining precision, accuracy, and repeatability in the lab, a liquid handling robot can assist. Some platforms are better suited to carry out serial dilutions, while others are useful for preparing PCR reactions and the extraction of nucleic acids.

Some of the most common automated liquid handling applications include:

- Molecular biology assays

- Epigenetics and genetics

- Drug development and biological research

Choosing an Automated Liquid Handling Platform for Your Laboratory

When it comes to choosing the right liquid handling system, you're going to want to make sure you get it right the first time. Do your research and choose the best system for your needs. That way, you can be sure you're getting the most out of your automated liquid handling system from day one. Here are some of the main questions to ask before you start evaluating systems to find your ideal platform.

- What are the main workflows you will be using the platform for?

- Do you need a fully-featured, single platform for all your liquid handling capabilities, or do you want to speed up one function in the lab – like dispensing, mixing, and washing samples?

- How much space do you have in your lab, and will the robotic liquid handling system have a dedicated station – or do you need it to be portable?

The answers to these questions will help narrow down your options. It's essential to prioritize your needs so you can evaluate each system for the best fit. Spending time understanding your current pain points and identifying where automation could assist will help you avoid making a costly mistake.

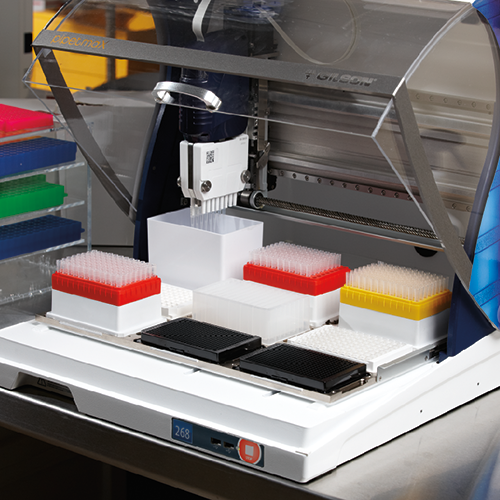

Figure 1: Gilson's PIPETMAX® Automated Liquid Handler

Benefits of Robotic Liquid Handling Systems

The benefits of these systems are almost endless. They include the ability to automate tasks, increase throughput, reduce sample-handling errors, measure volumes during dispensing processes, and optimize your entire liquid handling workflow for a walkaway process. Automated liquid handlers can be used for delicate operations such as drying samples for downstream processing, or injection and automatic fraction collection.

These systems can be scaled up or down depending on your needs. Smaller setups allow for a more flexible laboratory, while larger ones are ideal when you have high throughput requirements.

Robotic Liquid Handlers from Gilson

Gilson has been a leader in robotics and liquid handling systems since 1979. We have a range of automated liquid handling solutions available to help improve your throughput, maintain accuracy, and ensure higher repeatability.

- PIPETMAX® – Ideal for labs that need a best-in-class automated pipetting solution that provides you with maximum versatility, repeatability, and accuracy in a space-saving benchtop design. The PIPETMAX is ideal when working with smaller volumes of samples.

- GX-281 Liquid Handler - The perfect choice for laboratories that work with larger volumes or require up to 576 test tubes on the bed. The GX-281 comes with an efficient and open design while including a Jet Wash Rinse system for faster probe cleaning.

- GX-271 Liquid Handler – Suitable for scenarios where you need a versatile system with positive pressure SPE, liquid handling, and a large bed capacity that includes online integration with LC systems.

- GX-241 Liquid Handler – A two-rack platform for labs that need a small footprint solution for accurate and reliable injection and fraction collection of volumes between 100 μl and 10 ml. The VERITY GX-241 system takes up only 39 cm of linear bench space but can hold hundreds of samples ranging from 2 ml vials to 100 mm test tubes.

For any lab manager who needs to increase throughput while maintaining accuracy, contact Gilson to discuss our robotic liquid handling systems.