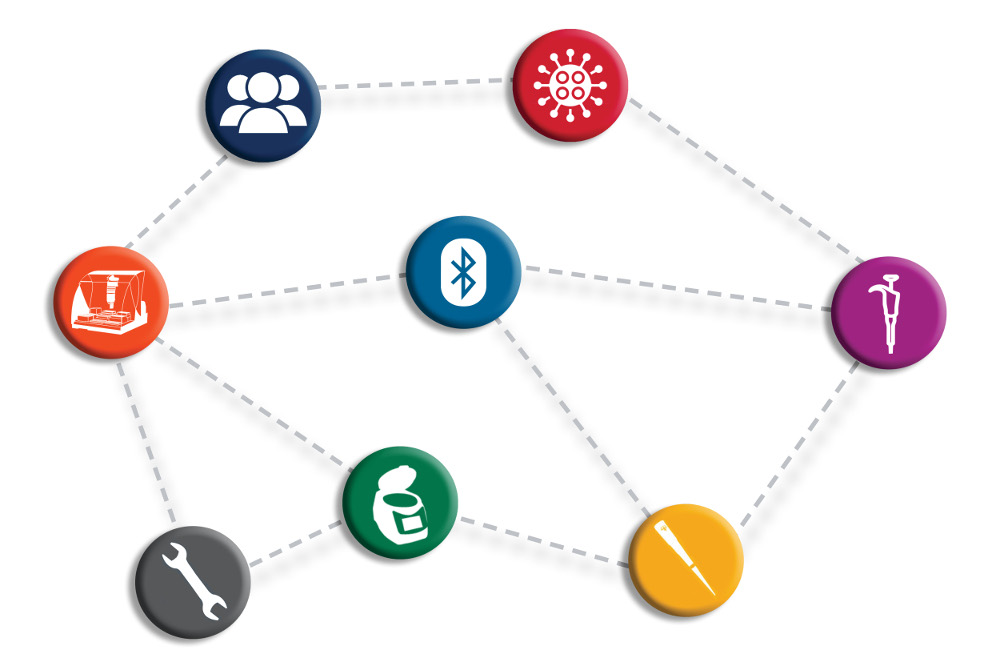

I-COVID is a rapid saliva-based COVID-19 test developed by the University of Illinois at Urbana-Champaign. To help broaden the use of the I-COVID test, the university founded SHIELD T3. The organization's name is a reference to its strategy ‒ target, test, tell. They target which populations to test and at what frequency, test those populations, and quickly report the results digitally and employ contact tracing. We recently spoke with Christian Messmacher, Chief Operating Officer of SHIELD T3, about the company, how their I-COVID test is expanding testing, and how he uses Gilson liquid handling tools to help facilitate the testing workflow.

Can you please tell us a little bit about SHIELD T3?

Christian Messmacher (CM): SHIELD T3 is a university-run organization founded by the University of Illinois. Its mission is to expand the reach of testing using the I-COVID test both nationally and overseas. The company was formed in July of 2020, and we're now setting up laboratories with the intention of replicating the success of the COVID-19 testing program at the University of Illinois Urbana-Champaign campus.

Widespread testing has been described by many as a "bridge" to a vaccine. However, supply chain limitations mean that frequent nationwide testing is challenging. Do you believe the "target, test, tell" T3 approach will be a game-changer, and how does it address those challenges?

CM: There is no question that the supply chain is going to be a challenge. Testing per se isn't very effective. It has to act in concert with active targeting of the people who need to be tested and a very active isolation and quarantine program. SHIELD T3 brings a whole ecosystem to testing that allows companies and universities to deploy a very robust ecosystem that monitors contagion rates and determines what individuals, or groups of individuals in a population, should be tested with the highest frequency. Next, we provide a very simple way of both contact tracing and managing access to congregate settings to reduce the spread. And the test has a very high degree of sensitivity, so we're often able to detect individuals infected before they become highly infectious, allowing them to isolate themselves before that happens.

What are the advantages you see in saliva-based testing compared to conventional COVID-19 test methods?

CM: The most important advantage is that it bypasses the RNA extraction step, which is a significant time and supply chain problem in the current testing regime. It is also a very simple and low-discomfort way to obtain a sample compared to nasopharyngeal swabs, which are used in conventional tests. And it produces very fast results.

COVID-19 Testing: Liquid Handling Solutions to Support Your Efforts

In today’s clinical environment, COVID-19 testing is of paramount importance and is growing in numbers on a daily basis. We’ve consolidated tools, technology, services, and resources showing how our lab solutions and systems can be integrated into your qPCR and RT-LAMP testing workflows.

Learn More

Can you walk us through the process from collection to reporting of results and the workflow?

CM: An individual deposits saliva into a vial, closes the vial, then sends it to a laboratory for testing. In the lab, the sample is denatured by heating the vial, then buffers are added to finish breaking down the enzymes in the saliva. The sample is transferred to a 96-well plate and then to a 384-well plate containing primers and probes, and RT-qPCR analysis is performed. Negative results get reported immediately, and positive results get retested for confirmation and accuracy.

Given the process you just described, why are organization, automation, and efficiency so important to success in a high-throughput lab?

CM: A high-throughput lab is more akin to a production line than it is to a scientific environment. In other words, we need a very consistent process that gets done exactly the sameway every time in order to ensure that we consistently have stable, predictable test outcomes. Preparing samples in a 384-well plate is a mind-numbing task, and after pipetting the first few times, it is very easy to make a mistake. I stand in awe of lab technicians who can do this job consistently. It requires a lot of willpower to stay focused. Having some automation allows us to facilitate the job for them, and in turn, allows us to scale up the process.

How did you become introduced to Gilson, and how did you choose Gilson as your liquid handling equipment provider for the workflow?

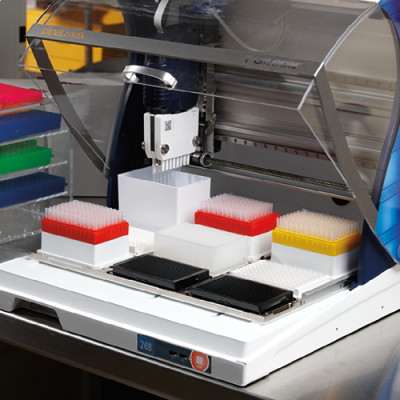

CM: We started looking at Gilson when we saw that the lab at the University of Illinois was using PLATEMASTER® for preparing plates. When we looked at the product line, there were a lot of things we liked about it. Our business model is to create what we would almost call a laboratory in a box. We use a 53' dry cargo van that is converted into a Biosafety Level 2 (BSL-2) environment. And within that environment, we carry out the testing process in a very standardized fashion. As we were looking for automation equipment, we wanted something that would give us repeatability and minimize the footprint. It seemed like the Gilson equipment would do that very well. As we began looking at a couple of the products, we started having broader discussions about all of the products that could help the effort. And that's how we ended up selecting Gilson.

A high-throughput lab is more akin to a production line than it is to a scientific environment. In other words, we need a very consistent process that gets done exactly the same way every time in order to ensure that we consistently have stable, predictable test outcomes.

What problem has the PLATEMASTER 96-channel pipetting system been able to solve for you? How is the efficiency compared to a handheld pipette?

CM: PLATEMASTER allows us to do two things very effectively. The first one is preloading both the 96- and 384-well plates with the reagents used in the process. It also allows us to transfer samples very quickly from one or four 96-well plates to a 384-well plate. In general, it reduces the amount of work a technician would need to do for those steps in the process.

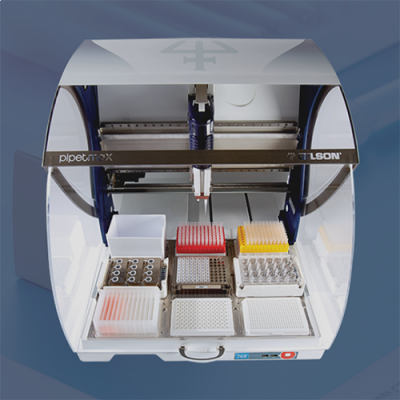

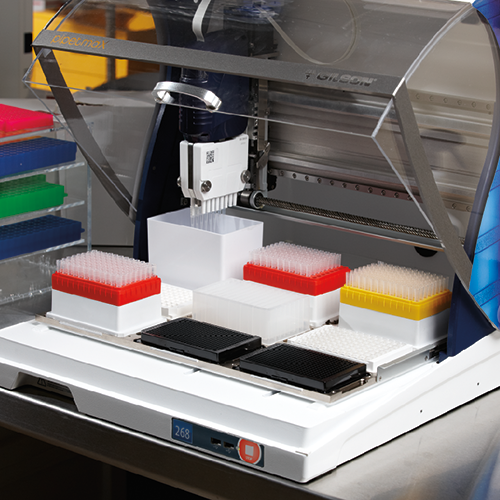

Each SHIELD T3 lab includes two PIPETMAX® instruments. Can you briefly describe the benefits of using those instruments for your workflow?

CM: The PIPETMAX instrument transfers the saliva samples from the original collection vials to 96-well plates. It essentially eliminates the manual work of doing that operation.

How do these tools compare to other fully-automated liquid handlers you have experience with?

CM: What I tend to like about the Gilson design is that it's simple. Other automation equipment I evaluated was made to do many things well, but we don't need that level of complexity. When I looked at the Gilson products, they looked like something that would work without a lot of complexity. In general, I'm a big believer in the philosophy that only that which in the beginning appears to be simple is even possible.

Not all test results are conclusive, and retesting is a key component of operation. Why did you choose the TRACKMAN® Connected pipette, and how does it support your retest workflow?

CM: When we looked at the testing workflow and the quality control of the workflow, it became very apparent that any manual operation would come with a high risk of making errors when transferring samples from one plate to another. We were looking for a simple way to reduce the probability of those errors happening. We initially started looking at automating that process, doing it on a robot. Still, we quickly decided that neither the volume nor the complexity of actually programming that workflow was worth it. We started looking for some kind of assistant for the employee. When we saw TRACKMAN Connected, we thought here again is a very simple solution that works.

Fulfillment centers have a similar problem. I spent many years doing projects for fulfillment centers using pick-to-light systems. You give somebody a list of items to pick up from a rack, and they need to come back with the correct items. Lights on the bins guide the worker to the correct location from which to get the item. When I saw TRACKMAN Connected I thought this is perfect. This is exactly the same concept applied to a microtiter plate.

You have purchased a variety of pipettes, including single channel, multichannel, motorized, and positive-displacement models. Why is it important to have so many different types of pipettes, and what is the value you see in selecting the right tool for the job?

CM: It's a matter of having the right tool for the job. Most of the team is not wedded to a specific method of doing things, but we wanted to look at the best way to do it. We've tried to match the right tool for the right job. If we are going to make a low-volume transfer or low-frequency transfers of items, we can use a manual pipette. At times we want the flexibility of not running a full 96- or 384-well plate, but we still want to fill the plates quickly. In those circumstances, having a multichannel pipette is very useful, especially one that is Bluetooth®-connected, like PIPETMAN® M Connected. It can work like a regular pipette or a repeater pipette, and we can program pipetting workflows. We are finding them to be very flexible, very powerful tools.

We have found that saliva is a fluid with incredibly variable viscosity. Especially in the symptomatic population, there is an incredibly high viscosity of the saliva samples. The positive-displacement pipettes seem to work a lot better for handling that kind of variability.

What are the next steps for you and SHIELD T3?

CM: We are definitely trying to expand the testing. We want to grow as fast as we can to help contain the epidemic, and hopefully, we can put ourselves out of the COVID testing business as soon as possible. That would be a great outcome to have. We believe we have a solution that will help communities and has the potential of saving tens of thousands of lives. And under those circumstances, it's really hard not to want to go fast.

Is there anything else you would like to discuss with us that we didn't ask about?

CM: I would like to mention how your field service differs from other companies. My experience is that your people have been spectacularly good. Not only are they incredibly responsive, but they know their stuff well, and they don't shy away from problems.

Liquid Handling Tools to Accelerate Your Testing Workflow

Contact us to learn more about how our solutions can help you increase productivity and expand your testing capabilities.

Contact Us