Modern labs need to bridge the gap between information and operational technologies (IT-OT) to stay ahead of the competition. Equipping your teams with modern instruments, integrated platforms, and accurate control software is no longer a cost-prohibitive endeavor. Instead, your lab can leverage OEM partnership benefits that speed up new drug discoveries, develop precise and repeatable analytical methods, and scale operations to manufacture the quantities required.

Globally, just the drug discovery services market reached $10.7 billion in 2020. Moreover, a biotech boom will continue to drive the market over the next decade as more organizations look for natural compounds with clear and definitive results in a variety of different clinical applications. To realize these opportunities, labs working in either analytical discovery or process-scale production should consider outsourcing their equipment and software needs by utilizing OEM partnerships as a cost-effective operational model.

Realizing OEM Partnership Benefits in Biotech Production and New Drug Discovery

Original Equipment Manufacturers (OEMs) allow labs to develop and deploy new methods covering the entire gamut of laboratory workflows. One of the main challenges when working with in-house and do-it-yourself systems in your workflow is running into issues that increase costs, requiring too much labor, or consuming too many materials like solvents to achieve the necessary quantities.

Most OEMs understand that partnerships are beneficial when both parties succeed. As biopharma and drug discovery labs start looking for new system integrations, process engineering solutions, and automated processes, OEMs are in a unique position to assist. Collaborating with an OEM gives you more than just the required equipment and software; it also grants you access to technical expertise, modern analytical capabilities, and new workflows or methods to help corner the market on an emerging compound or drug. Below we cover some of the major benefits available from partnering with an OEM to improve your laboratory workflows.

Reducing the Cost of Ownership

Although different partnership models exist, the cost of ownership of your new equipment remains the responsibility of the OEM when signing a partnership. You can also transfer other risks to your OEM partner and alleviate the burden of requiring in-house experts available who can operate, maintain, and service the instruments. OEMs train your staff to ensure they are familiar with the new capabilities, and you avoid the need for large capital expenditures.

OEM partnerships provide you with fewer surprise costs, create a buffer in your resource allocations, and help you benefit from a contractual obligation for the products and services you get. Additionally, lab automation and system scalability are part of your OEM partner’s skill set, ensuring you benefit from years of industry expertise. Although you will have to conduct your own research on your prospective OEM partnerships, you’re likely to find highly efficient workflows, a range of standard methods, and modernized quality assurance systems that often form part of the agreement.

A Variety of Liquid Handling Systems to Fit Your Needs

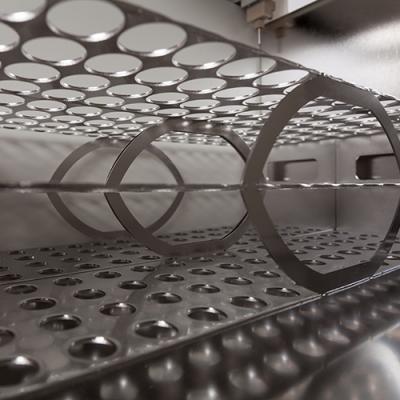

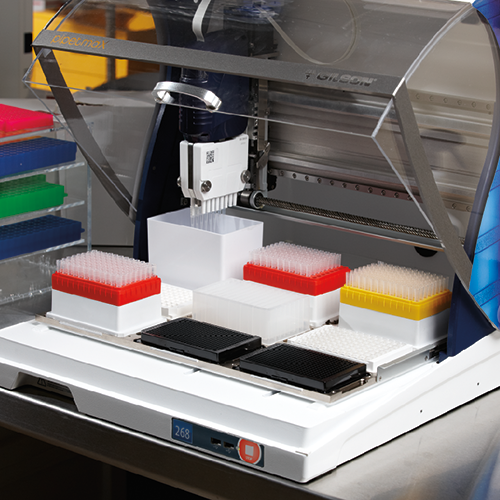

Our OEM automated liquid handling customization options are applied to our full range of systems across multiple applications, whether it’s a simple, small component or a complete liquid handling system.

LEARN MORE

Accelerating Your Time-to-Market

If you’re not first, you may miss a unique opportunity available in the market. Developing new drugs and extracting active biological compounds for commercial success can take years to perfect. OEM partners have the skills and abilities to analyze your original methods, develop a modern workflow, and help you scale to ensure you build a commercially viable operation. In the post-pandemic world, societies have a vested interest in drug development, certification, and distribution.

For drug researchers, developers, and producers, it is vital to address the shrinking gap between information technology and operational infrastructure. OEM partnerships give you access to innovative technologies, new analytical methods, and a wealth of technical expertise that help automate your processes. Predictions from a decade ago are coming true with advances in technology and demand for biomedical products. This has placed most clinical manufacturers under pressure. OEM partnerships are the ideal solution to overcome these challenges.

Flexible Production and Continuous Manufacturing Capabilities

OEM partnerships provide you with the tools you need to streamline existing workflows and automate many of your labor-intensive preparative processes. OEMs help you to simplify production strategies, adopt single-use technologies, and deploy disposable bioprocessing equipment that makes your drug discovery and production operations manageable and commercially viable. With an OEM partnership, you can develop a process that is effective, affordable, and economically beneficial to both parties.

Faster turnarounds of smaller batches are possible using consumables that don’t require cleaning, sterilization, or validation before a production run. OEMs provide support during every step of the process, helping you scale and guiding you with the latest information available from analytical workflows deployed in the industry. Once you have finalized your methods, OEM partners can recommend different systems and platforms that help you optimize every step in the workflow. From automated liquid handling to sample preparation and injection to final purification and analysis, OEMs work with your team to optimize your method and set up a continuous manufacturing workflow.

OEM partnerships provide you with fewer surprise costs, create a buffer in your resource allocations, and help you benefit from a contractual obligation for the products and services you get.

Dedicated Quality Management and Record-Keeping Capabilities

It’s not enough to accelerate your time-to-market if you cannot maintain the quality of your workflow. OEMs know what tools you need to keep accurate records and track every batch throughout your process while scaling your operations. Quality management is something OEM partners deal with every day in a wide variety of regulatory and legislative frameworks. You can define your needs and let your OEM partner help develop the required QMS for each stage of your process.

The right OEM partner works with you to manage the entire lifecycle of your products and maintain the required quality certifications in your process and equipment. In addition, OEM partnerships benefit organizations by ensuring your equipment operates as designed, receives the required services, and, when needed, assists by troubleshooting issues. If you need a workflow that’s scalable, cost-effective, and commercially viable, then OEM partnerships are one of the best available business models.

Customization Capabilities in the Time of COVID-19

Many labs had to pivot rapidly during the pandemic to address the new demand for diagnostic and research protocols. An OEM partner like Gilson can assist in these situations, specifically when you need to customize portions of your liquid handling workflows for increased throughput.

Gilson assisted a medical college in ramping up production by customizing the tube dispensing steps using our liquid handlers to process a minimum of 100,000 tubes of viral transport media (VTM) per week. Other Gilson OEM company partners have developed new, simpler coronavirus sampling techniques and faster testing workflows for confirmatory results. The value of having an OEM partnership that can help you adjust quickly in challenging times cannot be overstated.

Working with Gilson to Realize OEM Partnership Benefits

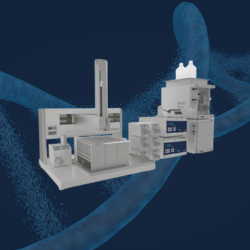

Gilson works with labs and drug manufacturers worldwide to find new, innovative, and cost-effective solutions to their operational problems. Whether it’s for purification, extraction, or bulk liquid handling systems, our engineers will assist with any workflow and help scale your process to the required production levels.

With decades of experience in manufacturing modern, efficient, and effective instruments, our team of experts has the knowledge, dedication, and expertise required to equip your modern laboratory. In addition, our range of versatile solutions enables Gilson to work with any organization that needs precise, repeatable, and verifiable results.

If you need to increase your capacity and want to see how an OEM partnership benefits your organization, contact Gilson for more information today.

Our OEM Expertise Makes Your Ideas a Reality

Bring your ideas to market faster and with lower development and manufacturing costs by becoming an Original Equipment Manufacturer (OEM) partner with Gilson. Our philosophy is simple: build and support relationships that are as strong and reliable as our products.

LEARN MORE